In the world of plastics, polypropylene (PP) stands out as a versatile and commonly used material. From packaging and textiles to automotive parts and consumer products, PP is everywhere in our daily lives. However, its ubiquity also means that understanding its recycling process is crucial for environmental sustainability. This article aims to demystify the basics of PP Recycling, offering insights into why it matters and how it works.

What Makes Polypropylene Popular?

Polypropylene is favored for its durability, resistance to moisture, and ability to withstand high temperatures. These properties make it ideal for a range of applications, including storage containers, medical devices, and even clothing fibers. Its lightweight nature also contributes to reduced shipping costs and lower fuel consumption during transportation.

Despite its benefits, PP can pose environmental challenges if not properly managed. Unlike biodegradable materials, PP takes hundreds of years to decompose, leading to accumulation in landfills and oceans. This highlights the importance of recycling initiatives and innovations that can help mitigate its environmental impact.

The Importance of Recycling Polypropylene

Recycling PP not only helps reduce landfill waste but also conserves energy and resources. Manufacturing new PP from recycled material requires less energy compared to producing virgin PP. This reduction in energy consumption leads to fewer carbon emissions, contributing to the fight against climate change.

Furthermore, recycling PP can lower production costs for manufacturers. By using recycled materials, companies can decrease their dependence on raw materials, which are subject to market fluctuations and geopolitical tensions. This stability can result in more predictable pricing for manufacturers and consumers alike.

The Polypropylene Recycling Process

The recycling process for polypropylene involves several key steps. First, PP items are collected and sorted from other types of plastic. This is crucial because mixing different plastics can compromise the quality of the recycled material. Once sorted, the PP is cleaned to remove any contaminants or residues.

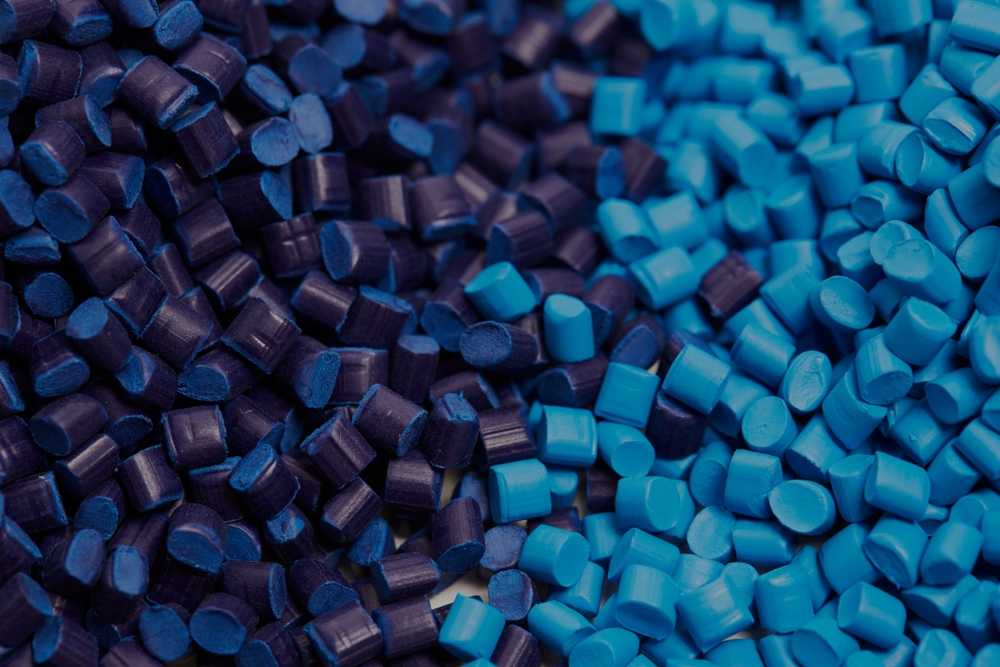

Next, the clean PP is melted down and reformed into pellets or granules. These pellets serve as the raw material for creating new PP products. It’s essential that this reprocessing maintains the integrity of the PP, ensuring that it remains suitable for its intended applications.

Challenges and Innovations in PP Recycling

Despite its benefits, recycling polypropylene presents challenges. One major hurdle is the contamination of PP with other materials, which can complicate the recycling process. Additionally, not all recycling facilities are equipped to handle PP, limiting the amount of material that can be effectively processed.

Innovations in recycling technology are addressing these challenges. Advanced sorting systems and chemical recycling methods are improving the efficiency and quality of PP recycling. These innovations hold promise for increasing PP recycling rates and reducing its environmental footprint.

How You Can Contribute to PP Recycling

Individuals play a vital role in supporting polypropylene recycling efforts. By properly sorting your recyclables and ensuring that PP items are clean and free from contaminants, you contribute to a more effective recycling process. Staying informed about local recycling guidelines can also make a significant difference.

Engaging with brands that prioritize recycled materials and support sustainable practices further amplifies your impact. Many companies are now incorporating recycled PP into their products, demonstrating a commitment to environmental responsibility.

The Future of Polypropylene Recycling

The future of polypropylene recycling looks promising as technological advancements and increased public awareness continue to drive progress. With ongoing research and innovation, the industry is poised to become even more efficient and environmentally friendly.

By understanding the basics of PP recycling and actively participating in sustainable practices, we can collectively work towards a cleaner, more sustainable planet. Polypropylene, while challenging, holds immense potential for positive environmental change when managed responsibly.